- Home

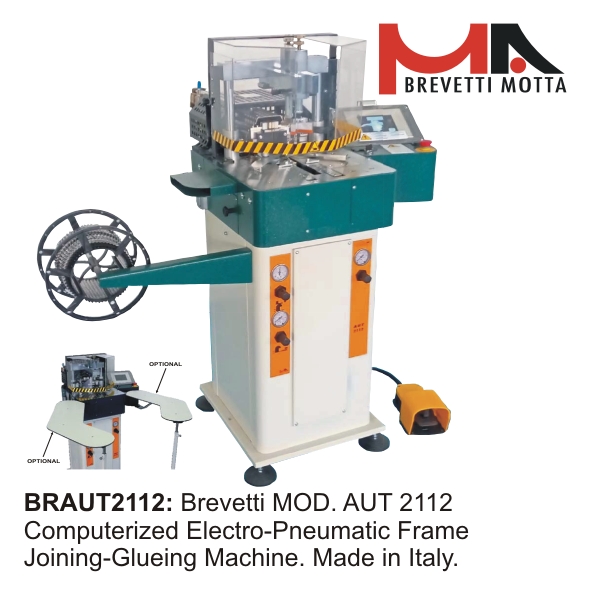

- BRAUT2112: Brevetti MOD. AUT 2112 Electro-Pneumatic Frame Joining-Glueing Machine. Ask us for a Quote!

Product Description

BRAUT2112: Brevetti MOD. AUT 2112 Electro-Pneumatic Frame Joining-Glueing Machine. Ask us for a Quote!

|

Product Code : BRAUT2112 Availability : Low Stock Video : AUT 2112.mp4 |

|

BRAUT2112: Brevetti MOD. AUT 2112 computerized heavy duty nailing-glueing coil fed machine with automatic spreading of hot glue and the insertion of nails. . Up to 10 different joining positions. . More than 1000 profiles memory. . Wide joining capacity. . Nails in coils type NR for MDF and hard woods profiles of medium or large sizes. . Nails in coils type VM for soft woods profiles of medium or large sizes. . Nails in coils type VC for softer woods or thin profiles of any material (soft-hard or MDF). . Recommended in all sectors for companies with large productions where the request of the glue in the joined corners is necessary or compulsory. . This model is very versatile. Main Characteristics: Computerized electro-pneumatic joining-glueing machine for the assembly of any shape and kind of frames either square, hexagonal, octagonal and dodecagonal. The machine automatically glues, presses and joins. Machine supplied in three versions (at choice to specify with the order): - version with multiple nailing unit type UNI to use indifferently nails in coils type VM (for soft and not too hard woods) and type NR (for hard and very hard woods or compact materials as MDF) - version with nailing unit type NR to use nails in coils type NR (for hard and very hard woods or compact materials as MDF) - version whit stapling unit type VC to use staples in coils type VC (for soft woods or thin profiles also in MDF). The three nailing units are interchangeable on the same machine. These nails are available in different sizes, according to the height of mouldings. Possibility to insert nails automatically in up to 10 different pre-set positions along the base of the moulding , to stack up to 4 nails in each position and to memorize different working programs. The special electronic control box can easily be used by the operator to select or modify the working program and to check all movements of the machine. The machine is capable of joining mouldings from 10 mm. (3/8") in width and 6 mm. (1/4") in height up to 120 mm. (4 3/4") in width and 65 mm. (2' 1/2") in height. Equipped with automatic gluer for hot melt glue, electronic control with color touch screen, adjustable glue blade stroke and 3 working speed. Sound level: LAeq < 73.1 dB (A). . Minimum frames dimensions: 250 mm. (9 7/8") side length (it depends on moulding width). . Production rate: About 100/120 complete frames per hour (it varies with frames dimensions and with the number of nails in each corner). . Electric power: 220/240 V single phase (other voltage on request) 50-60 Hz. max consumption 2 Kw. For USA and Canada 220 V - 60 Hz as standard. . Compressed air: 6 bar; Max consumption 50 Nl/Cycle. . Overall dimensions and weight: width 850 mm. (33 1/2"); length 1100 mm. (43 1/4"); height 1300 mm. (51 1/8"); 185 Kg. (407 Lbs.). . Particularly suitable for furniture and picture frames manufacturers with medium and large productions, where it is necessary to use glue.